|

EXECUTIVE SUMMARY | STATUS |

|

|

| |

SonomaWall™ is nearly ready to go to market.

To this point, information about SonomaWall™ has been kept restricted to

give an acquiring company pre-market development time. |

|

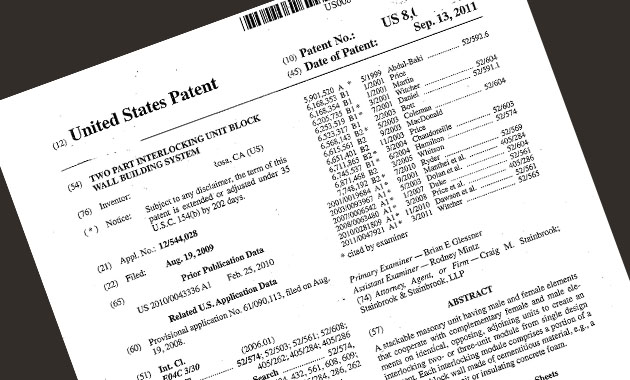

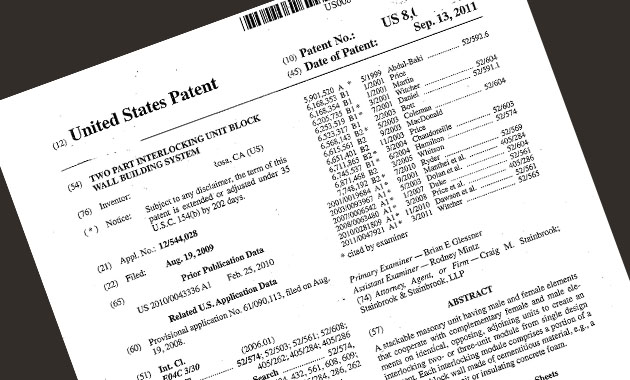

Intellectual Property

Upon reflection the original patent was little more than a design (apparatus) patent. Two patent law firms have added many CIP modifications to bring the intellectual property and the pending modifications to what is believed to be a very broad and defendable patent.

There is a series of additional CIP modifications that are still in various stages of the patent process. Foreign patents have been filed and are in process.

|

|

|

|

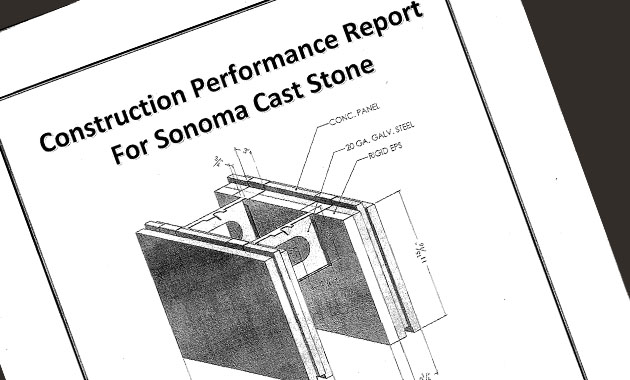

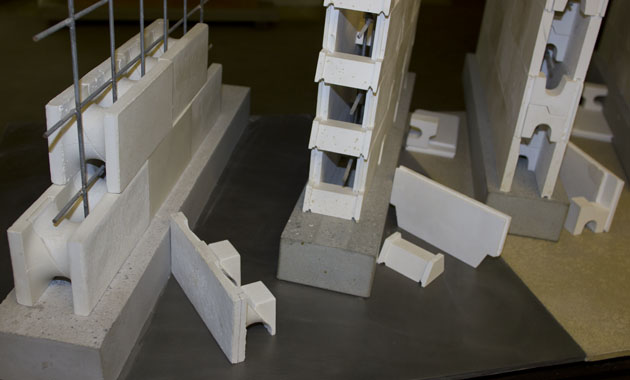

Structural Engineering

Independent structural engineering studies have shown that the SonomaWall™ has the same structural qualities as a reinforced solid concrete wall. Additional strength is anticipated when allowance for the added width and strength of the “retaining” panels are included in the study.

This portion of the study has yet to be completed. Varying block widths of the wall will allow for multi-story applications.

|

|

|

|

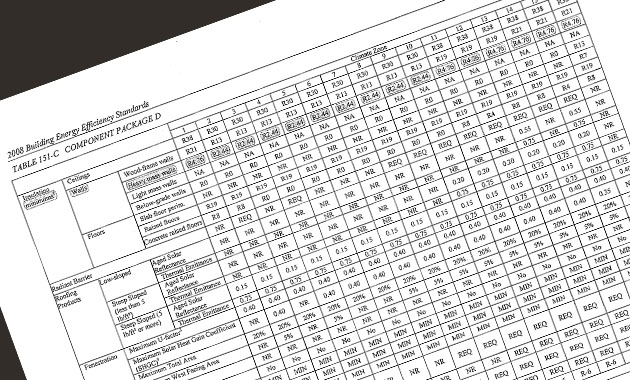

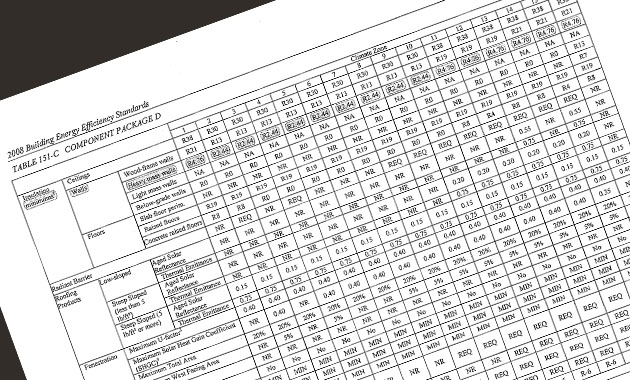

Thermal Engineering

The SonomaWall™ has the flexibility to include insulating foam, however, it is classified as a “heavy mass wall” and as such surpasses the insulative qualities of the highest rated “R-value” wall.

This designation gives an additional strength to the qualities discussed in the “Environmental Section” to make this a highly desirable wall for LEED® certification.

|

|

|

|

Environmental Assessment

Scientific Certification Systems, an independent environmental certification firm has determined that the SonomaWall™ should qualify for the special EPP Environmentaly Preferred Product – a major factor in the determination of a LEED® qualification.

|

|

|

|

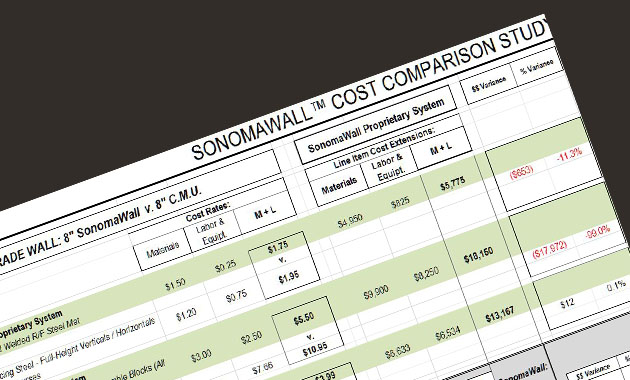

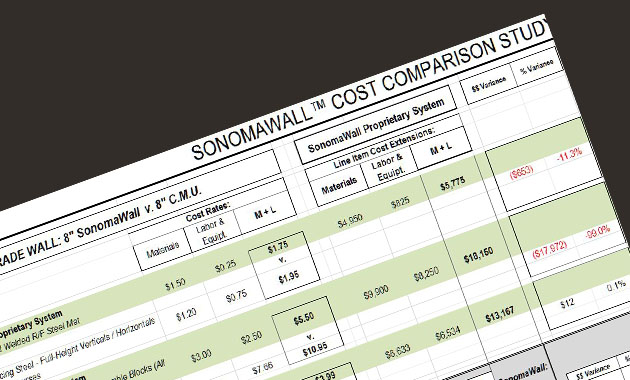

Economic Study

An Economic Study has been made by an independent construction forecast estimator. This study compared a hypothetical retail store wall (Target) with concrete tilt-up, stick frame and SonomaWall™ systems.

The results showed impressive comparisons for the construction grade SonomaWall™ and extraordinary savings when compared to finished walls that required secondary finishes.

|

|

|

|

Manufacturing Studies

Manufacturing studies have been completed showing the specifications and sources of the three main components to the SonomaWall™ System.

|

|

|

|

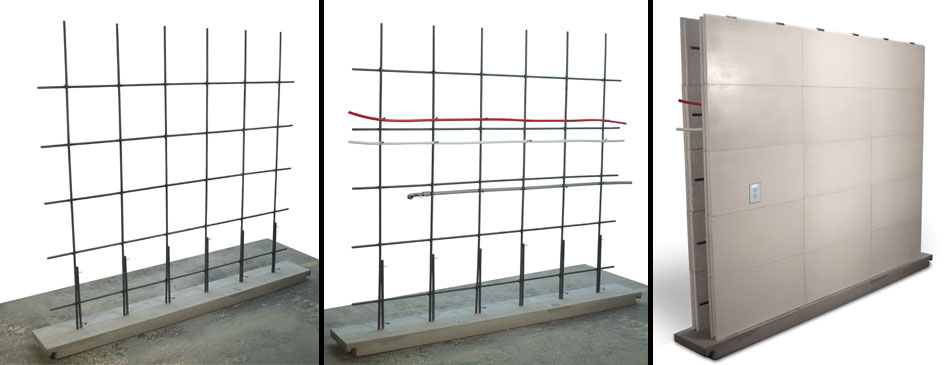

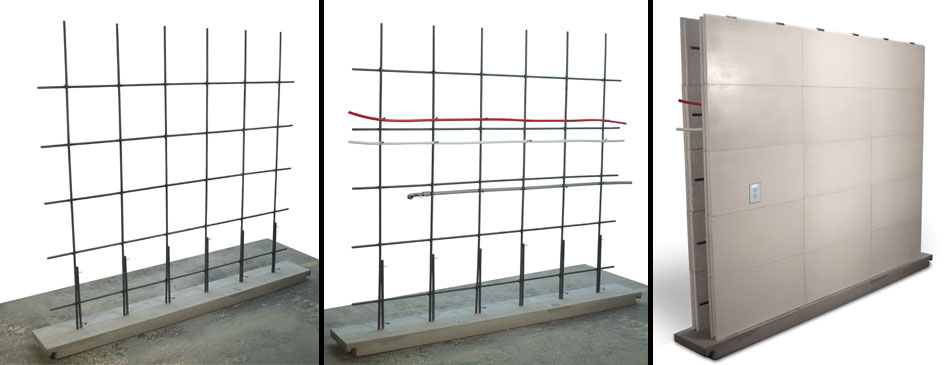

Rebar Grids

Rebar grids can easily be customized for each construction project. – These grids can be made on existing equipment. Production fabrication machines can take coiled rebar stock and automatically convert it into custom sized electro welded rebar grids.

With coiled rebar stock there is virtually no scrap and grids can be made and delivered for less than the material cost of hand cut and tied rebar grids.

|

|

|

|

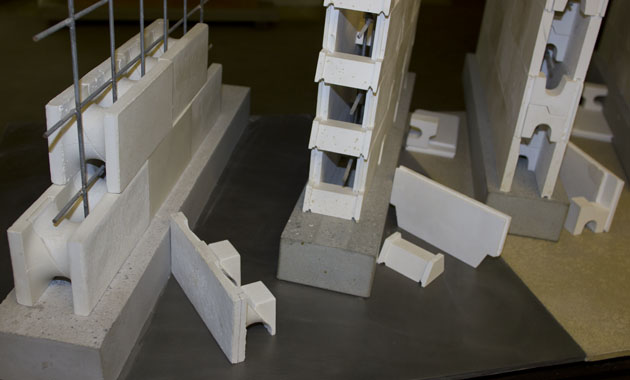

Retention And

Alignment Guides

These were originally made of fabricated steel for prototype purposes.

Replacement guides that are rustproof and do not conduct thermal transfer have been engineered and are ready for mass production.

|

|

|

|

Construction Grade

Surface Panels

Construction Grade surface panels have been designed to work on a wide variety of the most commonly available block making machines. Concrete block plants are plentiful in every state and every country.

|

|

|

|

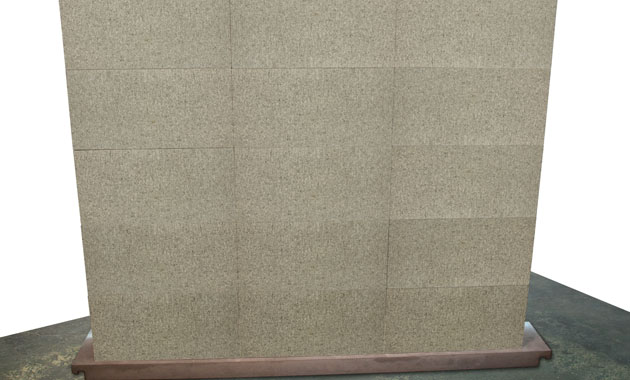

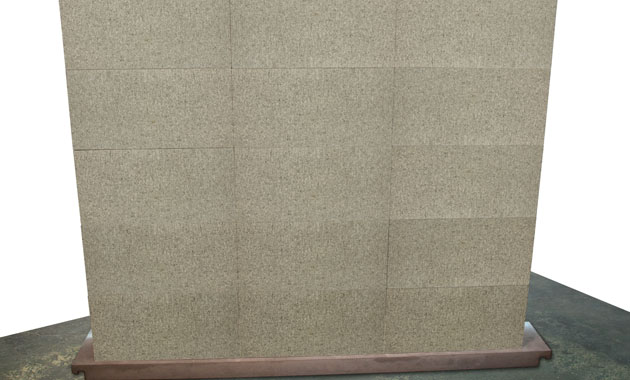

Finished Grade

Surface Panels

Finished Grade surface panels are made in large glass reinforced concrete plants.

With a highly automated system, a mold change can be accomplished with minimal investment. Companies that do multiple projects can develop their own proprietary identifying patterns and colors with ease.

|

|

|

|

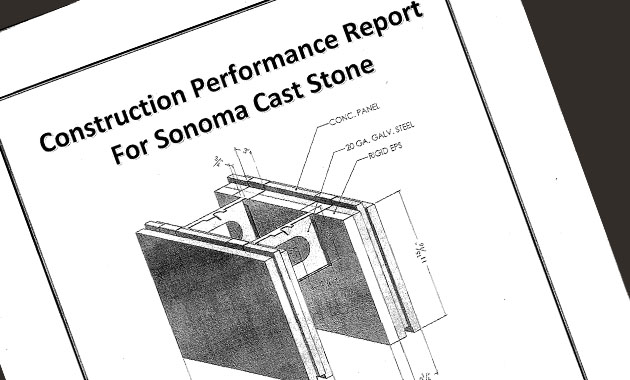

Surface Studies

Sonoma Cast Stone is one of the pre-eminent producers of luxury concrete products.

Over the past 16 years the company has perfected EarthCrete™, NuCrete™, MetalCrete™, SonomaLite and a number of unique colors, textures and finishes.

Many of these can be utilized in both the interior and exterior sides of the SonomaWall™ as shown in the “Design Opportunities” section of this product disclosure presentation.

|

|

|

|

Future Designs

There are a number of design improvements not publically shown that are in prototype stage. Some of these improvements are in patent application stages.

|

|

|

|

Personnel

An acquiring company should have existing personnel that could manage the marketing, engineering and manufacturing functions needed to bring the SonomaWall™ to the market place.

If desired, some of the existing personnel of Sonoma Cast Stone have expressed a willingness to help with the transition.

|

|

|

|

Economic Potential

This will vary by location. The potential is based upon the penetration of both the construction grade and a finished wall into the CMU, concrete tilt-up and stick frame markets.

No accurate records could be found that would give a country by country breakdown of these different construction methods. Construction is one of the largest industries in any country, and even with unreasonably conservative penetration ratios; the market for an improved wall system is enormous.

|

|

|

|

Environmental Ranking

The environmental ranking as an EPP (Environmental Preferred Product) and the unique designs and finishes should earn a modest 2% or 3% of the stick frame and the concrete tilt-up markets

|

|

|

|

Replacing CMU Blocks

When comparing performance, adaptability, design and primarily cost; both the construction grade and the finished grade (FMU) formats, the SonomaWall™ is vastly superior to the common CMU or cinderblock wall system.

As previously mentioned, construction walls are usually specified on the basis of cost and jobs are usually awarded as a result of competitive bidding. It is not unreasonable to take the position that in a number of years, the SonomaWall™ could totally replace the CMU block in developed or high labor cost countries.

|

|

|

|

info@sonomawall.com

©2012 Sonoma Cast Stone. All rights reserved. |